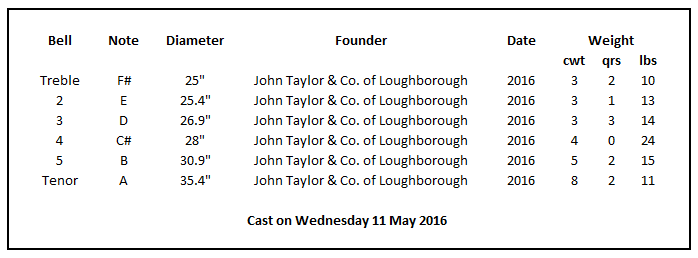

The New Bells

Wednesday 11 May 2016

35 people comprising donors, representatives from church, village, and local bell ringers travelled to the John Taylor Bell Foundry in Loughborough to witness the casting of the six new bells for Liddington. This was preceded by a very informative history of the company and an explanation of how and with what the bell moulds and bells are made, as we toured the tuning workshop, ropewalk, carpenters workshop and the museum.

The Tour Party The Carpenters Workshop

In the tuning shop

The casting was viewed from the purpose built gallery overlooking the busy foundry floor. The bell moulds had earlier been lowered into the sand filled casting pit.

Before the casting

The furnace was roaring away heating the bronze to 1100C, and creating a haze that enveloped the foundry, and at 3.30 pm, the master founder started proceedings. The treble bell was cast first followed by the 2nd, 3rd, 4th, 5th and tenor. Some 20 minutes later, it was all over and our guide led us down onto the foundry floor to take close up pictures.

Pouring Bell Metal Casting the treble bell

The bell castings were left to cool down for about a week, and then the moulds were broken open and the bells moved to the tuning shop. Ropes, wheels, clappers, and other bell parts were manufactured over the next 6 weeks before they were all delivered to Liddington on Friday 1 July 2016.

The bell frame under construction

Grants have been awarded towards the costs of the new peal of six bells, by the following:

Gloucester & Bristol Diocesan Association of Church Bell Ringers

Central Council of Church Bell Ringers

Allchurches Trust

Garfield Weston Foundation

Barron Bell Trust